Serving the CNC Industry Since 1960

Precision CNC Machining

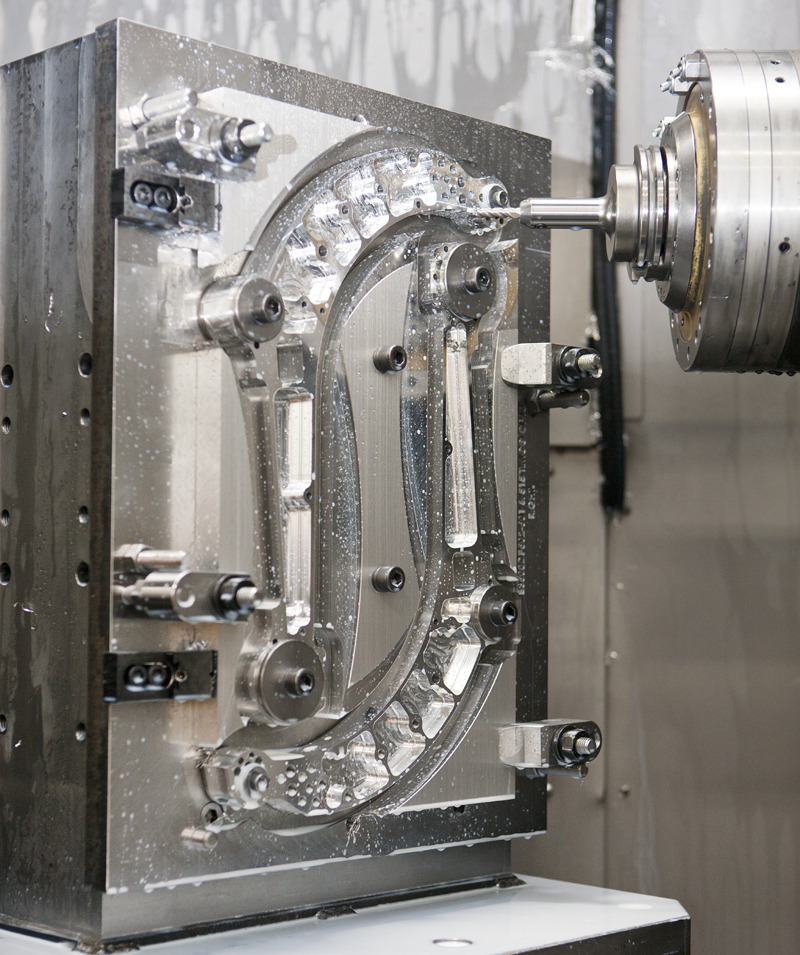

CNC Milling

CNC Turning

Assembly

Milling Capabilities

Our 3, 4, and 5 axis Vertical Mills are perfect for handling your smaller components, Our 10 Horizontal Mills are great for handling your larger components that require fast cycle times and higher volumes. With our integrated pallet change systems, the down time is practically seconds between cycles.

Turning Capabilities

PEMMCO Mfg. has invested in the latest technology when it comes to our lathe division. 14 of our 15 CNC Lathes are fully automated by either Robots or Bar-feeders. The automation drastically reduces your cost of components and you consistently receive your parts on-time due to the utilization of automation. We can manufacture parts from the size of a pencil tip to the size of a car tire.

Assembly

At PEMMCO Mfg. we offer the option to assemble your parts before we ship them to you. In fact, we have a whole department dedicated to this procedure. With our ability to do assembly, we lower your bottom-line and get your parts to you faster!

More Than Just CNC.

Located in the Asheboro, North Carolina, we are able to offer quick lead times, low cost and exceptional quality from our 75,000 sq. ft. facility built in 2011. Our robust Quality System is backed by ISO 9001:2015 & IATF 16949:2016 certifications which we have held for over 10 years. Our privately held company is here to provide you with the absolute highest of quality parts while still keeping your cost down.

Manufacturing Engineering

Waterjet Cutting

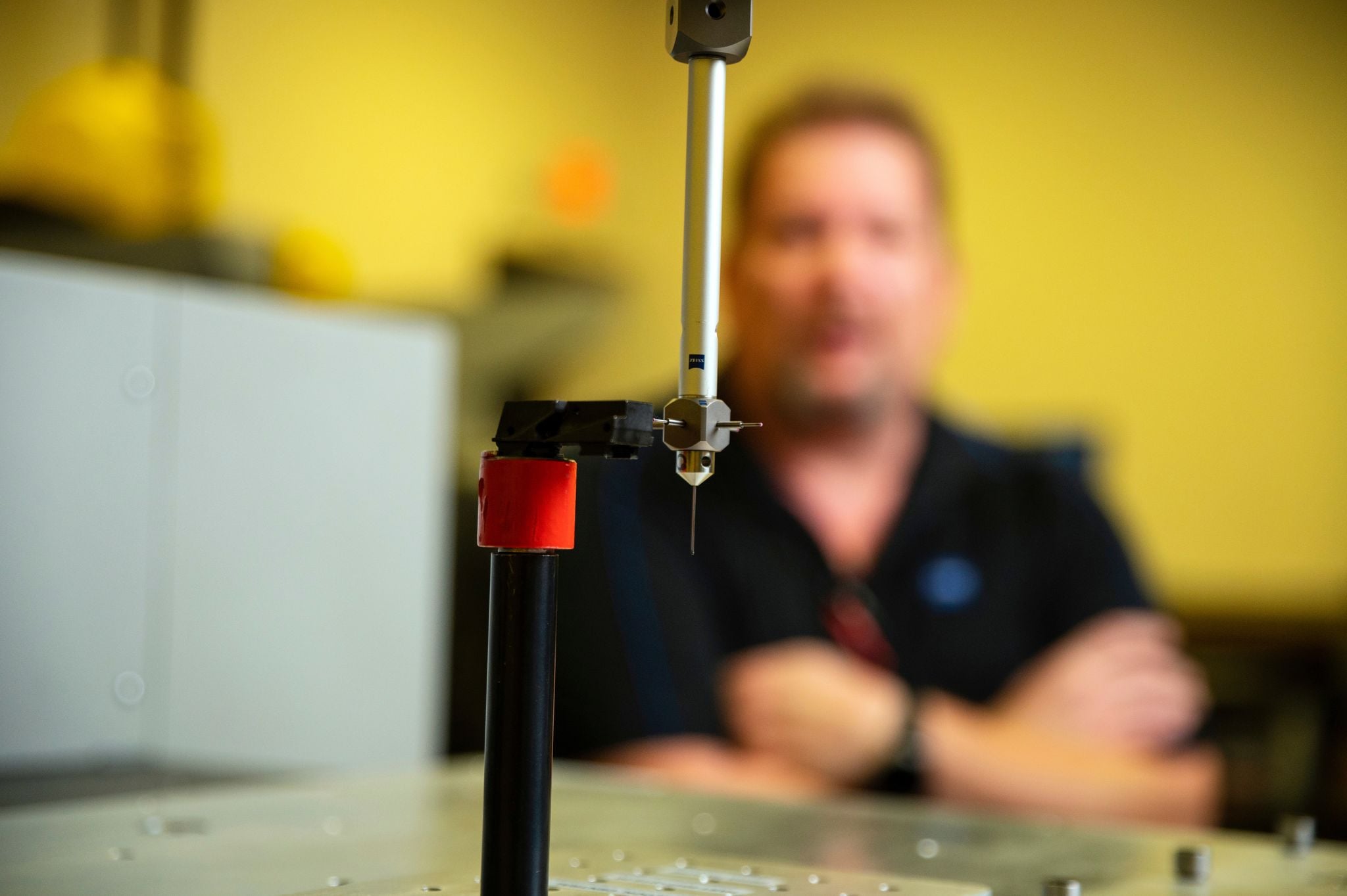

Metrology

Manufacturing Engineering

Our Vertical Mills are perfect for handling your smaller components that do not have a very large annual usage. Our Horizontal Mills are great for handing your larger components that require fast cycle times and higher annual volumes. With our integrated pallet change systems, the down time is practically seconds between cycles.

Metrology

We use GD & T to accuratelly measure parts that conform to our customers values and dimensions using our highly accurate Computerized Measuring Machines (CMM). This allows us to measure our parts down to microns. We also keep track with measuring tools on the shop floor to ensure our quality system is always in check. This allows us to consistently make quality customer parts.

Waterjet Cutting

Our 6 by 12 foot waterjet cutting tool is fully capable of cutting up to six inches of steel. We have the ability to manufacture blanks for production, or just a one time cycle for a drawing of your choice. with a cutting stream of 60,000 psi, we can cut just about anything on our waterjet.

Explore Our Other Services

Engraving

Spline Rolling

Engraving

One of the most important factors with our ability to satisfy our customers is the engraving of our own parts. We have two Telesis Laser engravers on the shop floor which allows us to cut out the middle man with parts that need to be engraved. This allows us to get you your parts faster, while also allowing for a smaller margin of error!